Sustainable Dock Design: Material Selection Insights

Introduction

Selecting the appropriate materials for dock construction is critical for ensuring long-term structural integrity, user safety, and environmental sustainability. You face challenges such as water corrosion, heavy loads, and regulatory compliance. This article guides you through evaluating material durability, safety, environmental stewardship, cost-effectiveness, regulatory standards, and aesthetics. You will learn how various materials perform under harsh marine conditions, contribute to user safety, affect the environment, and deliver long-term value. Expert insights, supported by real-world examples and scientific data, help homeowners involved in waterfront construction ensure that their docks remain safe, efficient, and sustainable for future generations.

Transitioning into the main content, the following sections address key questions regarding material performance and long-term viability in dock projects.

Evaluating Material Durability and Longevity for Dock Construction

When constructing your dock, understanding how materials withstand wear and tear is essential. Durability and longevity are determined by a material’s resistance to marine environments and weathering. Factors such as corrosion, ultraviolet (UV) degradation, and physical abrasion from water movement play key roles. Materials like stainless steel and high-density polyethylene perform well in both coastal and inland conditions due to excellent corrosion resistance and low maintenance needs.

Assessing Resistance to Marine Environments and Weathering

The primary concern is whether a material can resist the corrosive effects of saltwater or high humidity. You must evaluate how materials handle moisture, salt, and biological agents. For instance, composite decking often includes UV stabilizers and water-repellent treatments that extend its life beyond that of conventional wood. Materials like marine-grade aluminum have been observed to perform efficiently for 25 to 30 years with minimal discoloration, while protective coatings on metals help reduce degradation from sun exposure.

Understanding Load-Bearing Capacities of Different Dock Materials

Structural components such as piles, beams, and decking must handle dynamic loads from waves, user traffic, and mooring forces. Examining stress-strain performance and fatigue limits is crucial. High-strength concrete and steel reinforcements are popular because they reliably support heavy loads. Reinforced concrete docks, when properly maintained, can sustain heavy loads over decades. It is important to consider not just current loads but also potential increases in dock usage.

Comparing Lifespan Expectations for Common Dock Construction Choices

Materials differ in lifespan based on maintenance and environmental exposure. Pressure-treated lumber typically lasts 15–20 years, while marine-grade polymers and composites often exceed 30 years. Metals such as galvanized or stainless steel, when maintained, have a competitive lifespan with modern composites. A lifecycle cost analysis shows that higher upfront costs for durable materials can lead to long-term savings due to reduced maintenance and repair expenses.

Maintenance Requirements for Preserving Material Integrity Over Time

Regular maintenance is crucial. This includes routine cleaning, periodic resealing, and inspections for early wear or corrosion. Wooden docks benefit from scheduled treatments against rot and pests; non-porous materials like fiberglass or plastic composites require minimal upkeep. An effective preventative maintenance routine preserves material integrity and minimizes downtime.

Evaluating Materials for Safe, Sustainable Dock Construction

Safety is paramount in dock construction since it directly affects user protection during normal and emergency operations. It is important to evaluate materials for inherent safety features such as slip resistance, non-toxicity, and fire resistance.

Selecting Slip-Resistant Surfaces to Maximize Dock User Protection

The dock surface must provide high traction even when wet. Surface treatments like textured composite panels, non-slip coatings, and perforated decks have proven effective in reducing slip incidents. Research indicates that anti-slip surfaces can reduce fall risks significantly compared to untreated surfaces. Always ensure material options meet regulatory slip resistance standards and are independently tested for high-moisture conditions.

Identifying Materials Free From Harmful Leaching Chemicals

Chemical safety is crucial when docks come into contact with recreational or fishing waters. Select materials that do not leach harmful chemicals, such as non-toxic sealants and eco-friendly composites. Certifications like GREENGUARD or ECOLOGO confirm a material’s safety profile and help ensure that no hazardous substances are released into the water.

Examining Fire Resistance Qualities of Various Dock Building Options

Fire-resistant materials are especially important in areas with high sun exposure and heat. Certain concretes and treated polymers offer inherent fire resistance. Fire-retardant panels can slow flame spread, providing additional safety time during emergencies. Choosing materials with proven fire resistance ratings and consulting local fire safety guidelines are key measures for enhancing docksafety.

Ensuring Structural Soundness Through Correct Material Application

Even the strongest material offers little benefit if not applied correctly. Standardized construction practices, correct installation of fasteners, regular inspections, and appropriate reinforcements are essential. Quality control during installation helps to detect and address deficiencies before they become hazards. Working with experienced builders who follow manufacturer specifications and local codes ensures a durable and safe dock.

Analyzing Environmental Stewardship in Dock Material Choices

Modern dock construction increasingly emphasizes minimizing environmental impact. Choosing sustainable materials not only meets regulatory requirements but also protects marine ecosystems and reduces long-term harm. Assessing the sourcing and processing of materials can have a positive environmental impact.

Sourcing Renewable and Recycled Content for Dock Structures

Select materials with renewable or recycled content, such as sustainably harvested lumber or recycled plastic composites. These choices reduce dependency on virgin resources and lower the material’s overall carbon footprint. Third-party sustainability certifications and transparent supply chains help verify renewable content and support environmental stewardship.

Calculating the Carbon Impact of Material Manufacturing and Logistics

Every material has an associated carbon footprint from manufacturing, transportation, and installation. Locally sourced materials typically require less transportation and generate lower emissions. Life cycle assessments help quantify these impacts. Opting for low-carbon alternatives or materials produced under carbon-neutral processes can substantially reduce the dock’s environmental footprint.

Material Effects on Water Purity and Aquatic Life

Materials that release harmful substances can negatively affect water quality and disrupt ecosystems, reducing biodiversity and impacting local fisheries. Inert materials, such as marine-grade concrete and certified eco-friendly composites, interact minimally with water chemistry. It is important to ensure that materials do not leach degradation products that could compromise aquatic health and violate environmental standards.

Decomposability and Disposal Solutions for Dock Elements at End-of-Life

At the end of a dock’s service life, proper disposal or recycling is essential. Some materials, like untreated wood, are biodegradable but may release pollutants if not managed correctly. Other materials, such as high-density polymers or metals, can be recycled with minimal environmental impact. Planning for recycling, repurposing, or safe disposal helps contribute to a circular economy while reducing landfill waste.

Balancing Initial Outlay With Enduring Worth in Material Selection for Docks

Cost-effectiveness is a major factor in material selection. While the upfront cost may be appealing, it is important to balance it with long-term maintenance, restoration, and durability considerations.

Upfront Purchase Prices for Different Categories of Dock Materials

The initial cost of materials varies with quality, brand, and supplier. Premium options like marine-grade stainless steel or engineered composites may cost more than traditional wood. However, these higher costs may be offset by longer lifespan, reduced upkeep, and fewer repairs. Understanding market trends and comparing vendor quotes supports informed decision-making tailored to your budget.

Incorporating Future Upkeep and Restoration Costs

Long-term costs, including maintenance and restoration, play a significant role in overall value. While pressure-treated lumber may have a lower purchase price, periodic sealing and repairs can add to its lifecycle cost. A total cost of ownership analysis that includes forecasted maintenance expenses can help determine which material offers the best long-term value.

Financial Returns From Resilient and Green Material Investments

Investing in high-quality, durable, and sustainable materials yields benefits beyond immediate cost savings. These include reduced downtime, lower maintenance burdens, and enhanced property values. Additionally, environmentally sustainable docks may qualify for green building certifications, potentially increasing marketability and property value.

Supply Accessibility and Cost Variations for Dock Building Components

Reliable suppliers and consistent access to materials are key for project planning and budgeting. Factors such as seasonal price fluctuations and geographic availability can impact both cost and timelines. Sourcing locally when possible may reduce costs and lead times. Proactive bulk pricing negotiations and contingency plans for supply variations ensure that material availability does not delay construction.

Meeting Regulatory Standards and Securing Approvals for Dock Materials

Compliance with regulatory standards is non-negotiable in dock construction. Local building codes, environmental regulations, and safety guidelines must be met to ensure legal compliance and enhance overall project performance.

Comprehending Local Ordinances for Dock Building Projects

Local regulations vary by waterway and dictate guidelines for structural integrity, environmental impact, and safety features. Before material selection, verify that the options meet all local zoning laws, building codes, and watercraftmooring requirements. Consulting with local regulators or experienced maritime construction professionals can help avoid legal challenges and costly modifications later in the project.

Material Properties Needed for Environmental Clearances

Many projects require environmental clearance certificates that specify material properties such as non-toxicity and low particulate emissions. Materials should be certified to have minimal disruption to local flora and fauna and to preserve water quality. Referencing recognized environmental certifications can streamline the clearance process and ensure compliance with strict environmental standards.

Compliance With Guidelines for Secure Watercraft Mooring and Access

Materials used in mooring systems and access areas must ensure secure anchoring without compromising structural integrity. Regulatory bodies set strength and fatigue criteria that can be met through standardized testing and third-party validations. Ensuring that your material selection includes components that satisfy these guidelines guarantees a reliable and safe dock system.

Opting for Materials Sanctioned for Use in Designated Aquatic Areas

Many regional and state agencies publish lists of approved materials tested for aquatic use. Choosing products from these lists minimizes the risk of regulatory violations and expedites project approvals. Such materials have undergone rigorous quality assurance and environmental impact assessments, ensuring reliable performance in real-world conditions.

Considering Aesthetic Qualities and Functional Needs in Sustainable Dock Material Selection

Aesthetics and functionality must be balanced. The selected materials should complement the surroundings, enhance visual appeal, and provide practical benefits for everyday use.

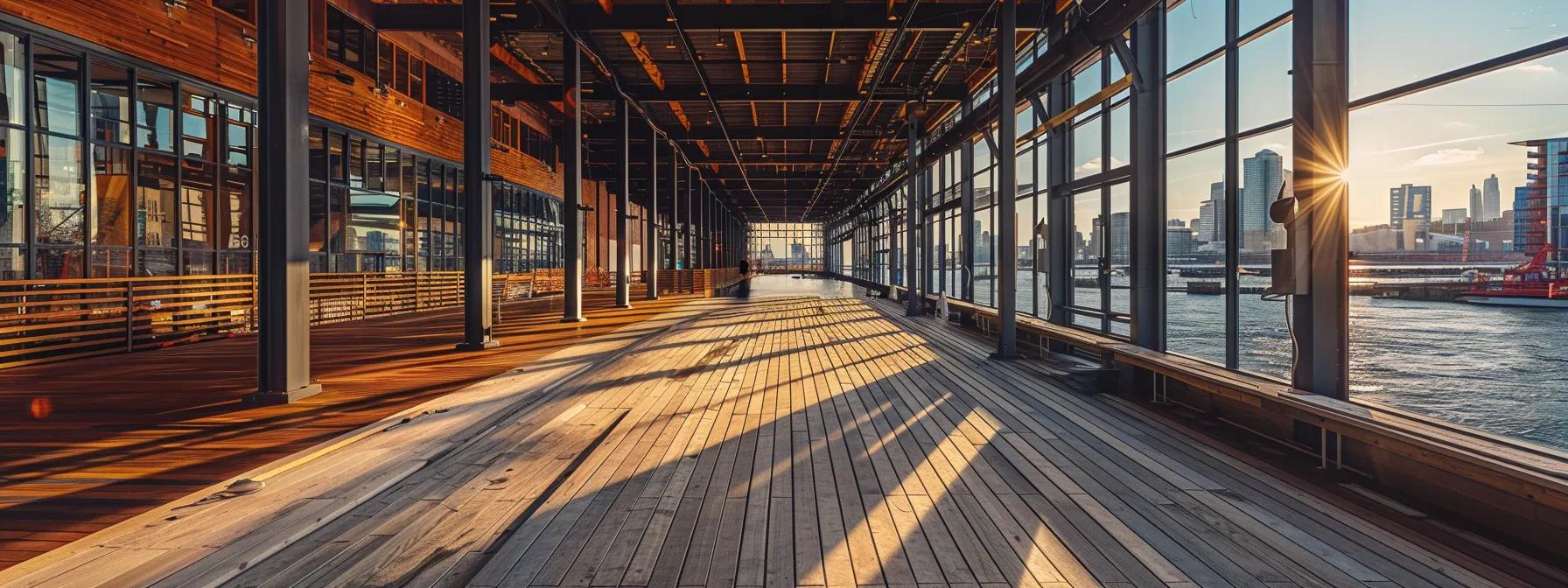

Aligning Material Look With Existing Architecture and Natural Surroundings

The visual appearance of materials, including color stability, texture, and finish, affects the dock’s appeal. Choosing natural wood with weather-resistant finishes or composites that mimic timber can enhance aesthetic value while ensuring durability. Consider how the material will weather over time when exposed to sunlight and saltwater. An integrated design that matches local architecture adds value to the property.

Material Choices for Personalized Dock Additions and Fittings

Personalization adds charm and functionality. Materials that can be easily customized allow for tailored design elements such as railings, benches, lighting, and storage. Modular composite systems can be shaped into unique patterns that blend traditional and modern aesthetics, enhancing user satisfaction and property value.

How Material Selection Influences Overall Dock Practicality and Enjoyment

A practical dock facilitates ease of use, accommodates various boat types, and simplifies maintenance routines. Materials affect load distribution, impact resistance, and even noise insulation. For instance, insulated composite decks can reduce noise, while integrated ladder mounts and built-in storage enhance functionality. Evaluate each material for its contribution to the overall design and user experience.

Reviewing Color Stability and Finish Durability in Material Options

Materials that maintain consistent color and finish over time are essential for a long-lasting, attractive dock. Advanced coatings, high-quality stains, and UV-resistant composites help preserve appearance and reduce the need for repairs. Ensuring long-term visual harmony supports both aesthetic appeal and economic value.

Table: Comparative Analysis of Key Dock Materials

Before we proceed to the conclusion, review the comparative table below, which summarizes the performance attributes, lifespan expectations, safety features, and environmental impact of common dock construction materials.

| Material | Durability (Years) | Maintenance Requirements | Safety Features | Environmental Impact |

|---|---|---|---|---|

| Marine-Grade Aluminum | 25-30 | Low (Periodic cleaning, resealing) | High corrosion and fire resistance | Low carbon footprint |

| Pressure-Treated Wood | 15-20 | High (Regular sealing and coating) | Moderate slip resistance | Biodegradable but requires treatment |

| Composite Decking | 30+ | Minimal (Occasional cleaning) | Excellent non-slip surface | Recycled content available |

| Reinforced Concrete | 30-40 | Moderate (Periodic inspections) | High load-bearing capacity | Energy-intensive production |

| High-Density Polyethylene | 25-30 | Minimal (Resistant to UV and water) | Very low chemical leaching | Recyclable and low toxicity |

This table shows that while costly materials like composite decking and reinforced concrete offer excellent longevity and safety, each option has unique benefits and drawbacks. Evaluating these factors based on your specific needs is essential for a wise investment.

Final Thoughts

Selecting the right material for dock construction requires balancing durability, safety, environmental responsibility, economic factors, regulatory compliance, and aesthetics. Prioritize materials that withstand harsh marine conditions while offering long-term savings through reduced maintenance. Consider environmental impact and sourcing practices to ensure sustainable construction that benefits both your property and the ecosystem. By investing in high-quality, safe, and sustainable materials, you create a dock design that enhances functionality, user experience, and property value for decades. Your informed choices today pave the way for a durable, user-friendly, and environmentally responsible dock for future generations.

Frequently Asked Questions

Q: How do I determine which dockmaterial is most durable for my project? A: Assess durability by evaluating resistance to marine corrosion, weathering effects, and load-bearing capabilities. Materials like marine-grade aluminum, high-density polyethylene, and composite decking have been shown to offer superior longevity. Consider local environmental conditions and maintenance requirements.

Q: What safetyfeatures should I look for in dock constructionmaterials? A: Look for slip-resistant surfaces, fire resistance, and non-toxicity. Textured surfaces, non-slip coatings, and fire-retardant treatments all enhance safety. Additionally, ensure materials are free from harmful chemicals that could leach into the water.

Q: How can I ensure my dockmaterials meet environmental regulations? A: Choose materials with sustainability certifications and low carbon footprints. Confirm that materials contain renewable or recycled content, and check for third-party environmental approvals. Performing a life cycle assessment also supports compliance with environmental standards.

Q: What cost factors should be included in a total cost of ownership analysis for dockmaterials? A: Consider the upfront purchase price, maintenance expenses, and potential restoration costs. Indirect benefits such as increased property value and reduced downtime also factor into a complete cost analysis.

Q: How does material selection influence the dock’s overall aesthetic appeal? A: The choice affects color stability, texture, and finish durability. Materials that mimic natural elements and maintain their appearance over time enhance the dock’s look. Consistency with surrounding architecture is also important.

Q: What maintenance practices are recommended for different dockmaterials? A: Wooden docks require regular sealing and treatment against rot and pests. Metals may need periodic cleaning and protective coatings. Composite and high-density plastic materials usually require minimal upkeep, primarily routine cleaning to remove salt and grime.

Q: Why is it important to consider both upfront cost and long-term value when choosing dockmaterials? A: Upfront costs impact initial budgets, but long-term value includes durability, maintenance, and replacement expenses. High-quality, resilient materials may have higher initial costs but can result in lower overall expenses and a more sustainable solution.