Understanding the Timeline: How Long Does Dock Construction Really Take to Complete?

When planning a dock construction project, many factors impact the overall timeline from the initial consultation to the day you launch your boat. This article covers each stage—from site assessment and design to permitting, material procurement, on-site activities, final inspections, and clean-up. You will learn how dock size, material choices, water body characteristics, and custom features influence project duration so you can manage expectations, plan budgets, and schedule efficiently with your contractor. Ultimately, understanding these factors ensures your dock meets both aesthetic and functional needs while being built within a realistic timeframe.

Transitioning from planning to execution, we now explore the detailed process and its time implications across different construction stages.

Defining the Scope of Your Dock Project and Its Impact on Duration

The overall duration of dock construction is directly linked to the project’s scope and design. Various elements—such as dock size, material selection, custom features, and site-specific water conditions—affect the timeline.

Initial Consultation and Site Assessment Duration

The initial consultation and site assessment set the groundwork for the project. Professionals evaluate site characteristics like water depth, current flow, and soil conditions. These assessments, along with discussions about your requirements and design preferences, help anticipate issues like water damage or flood risk. Typically, this phase takes one to two weeks; more complex sites may require additional time. Early identification of challenges can save significant time during construction.

How Dock Size Influences the Construction Timeline

Dock size is a primary determinant of construction time. Larger docks demand more extensive foundation work, additional piles, and longer framing and decking assembly. For example, heavy-duty piling installation for an extended dock can add several days compared to a simpler project. Larger dimensions also mean more material procurement, which may delay the schedule if materials such as marine-grade wood or stainless-steel fixtures are not immediately available. Planning dock size carefully helps set realistic timelines with your contractor.

Material Choices and Their Effect on Project Length

Material selection impacts both durability and construction duration. Docks built with concrete or metal often require additional curing or cooling time, adding days to the schedule. In contrast, wood or composite materials may speed up assembly if readily available. Certain materials require special installation methods—for instance, a pile driver works best with heavier materials, while lighter ones can be installed manually. Balancing longevity, maintenance, and project timelines is essential; any delay in material delivery or specialized installation can alter the projected completion date.

Custom Features and Additions Extending the Build Time

Custom features such as boat lifts, integrated lighting systems, or unique railing designs can extend dock construction timelines. These features require extra design work, additional material procurement, and often specialized labor. For instance, installing a stainless-steel boat lift involves precise measurements and extra installation stages. Similarly, a custom boathouse extension or covered dock area may stretch the schedule. Discussing these features early with your contractor ensures proper scheduling and minimizes delays.

Assessing Water Body Characteristics and Their Time Implications

Water body characteristics, including tidal patterns, temperature, and current strength, affect how the dock’s foundation is set. In areas with highly variable water levels or high erosion risk, additional reinforcement and specialized piling techniques are needed. These conditions may extend the preliminary phase as detailed surveys or environmental reviews become necessary. Understanding local water conditions early in the project lets you plan for potential delays and tailor the design to your site’s specific needs.

The Permitting Process What to Expect for Dock Construction Timeframes

Navigating the permitting process is a critical phase that impacts the overall construction timeline. Regulatory compliance, local approvals, and environmental reviews all shape the project’s duration.

Navigating Local Regulations and Approval Durations

Local regulations and zoning laws vary widely and influence both dock design and timing. You must secure multiple permits—including building, environmental, and waterway access permits. Depending on the jurisdiction, approval can take a few weeks to several months. Working closely with local authorities and, if needed, engaging a permitting consultant helps ensure regulatory requirements are met promptly and reduces the risk of unexpected delays.

Typical Timeframes for Securing Necessary Permits

Securing permits is not always straightforward. Timeframes can range from one to three months, depending on project complexity and the efficiency of local governmental bodies. Applications may undergo several rounds of review and public consultation. For instance, an environmental impact assessment might take as long as six weeks in ecologically sensitive areas. Knowing these typical timeframes in advance helps you build contingency time into the project schedule.

How Environmental Reviews Can Alter Your Project Schedule

Environmental reviews ensure that dock construction will not harm nearby ecosystems. Conducting these reviews may require additional data collection and analysis, which can extend the permit process. For sites near protected wildlife or sensitive habitats, extra documentation and precautions become necessary. Anticipating these delays allows you to work efficiently with environmental experts and helps ensure your project complies with all standards.

Working With Professionals to Expedite Permit Acquisition

Experienced permitting consultants and local professionals can expedite the permit acquisition process. Their established relationships with municipal agencies often reduce back-and-forth communications and help ensure all documentation is timely and accurate. By engaging such professionals early, you can achieve a smoother transition from planning to construction and potentially reduce the overall timeline.

Pre-Construction Preparations How Long Until Building Begins

Before physical construction begins, several pre-construction activities ensure the project is on track. Finalizing design details, planning infrastructure, and aligning contractor schedules with material delivery and site readiness are all critical steps.

Finalizing Design Specifications and Engineering Plans

Finalizing design specifications and engineering plans marks the end of the planning phase. Architects and engineers develop detailed blueprints, structural calculations, and safety protocols for the dock. This final design review, which may involve customer revisions based on site challenges, typically takes two to four weeks. Comprehensive, pre-approved specifications help reduce misunderstandings and avoid delays during later construction stages.

Contractor Scheduling and Mobilization Lead Times

Once designs are finalized, the contractor coordinates a start date, secures the necessary team and equipment, and schedules any required subcontractors. Mobilization usually takes several days to a couple of weeks, depending on the contractor’s workload and logistical challenges. Weather changes or adjustments in work plans may require rescheduling. Effective communication and advanced planning help synchronize all parties and set a realistic commencement date.

Material Procurement and Delivery Schedules

Procurement of construction materials such as marine plywood, piling, stainless steel fixtures, and composite decking is another key factor. The time needed to procure these materials depends on their availability. For example, custom marine-grade wood might require lead times up to three weeks, while more common materials may arrive within days. Delays in material delivery can postpone the overall timeline, making it critical to plan for potential setbacks early.

Site Preparation Activities Before Construction Starts

Once materials are ordered and contractors mobilize, site preparation begins. This process includes clearing the dock area, marking the foundation, and any necessary land grading. Depending on site conditions and task complexity, site preparation can take from several days to a couple of weeks. Extra work, such as shoreline stabilization or tree removal, may add time. Thorough preparation ensures the ground is ready to support the dock foundation and that construction proceeds smoothly.

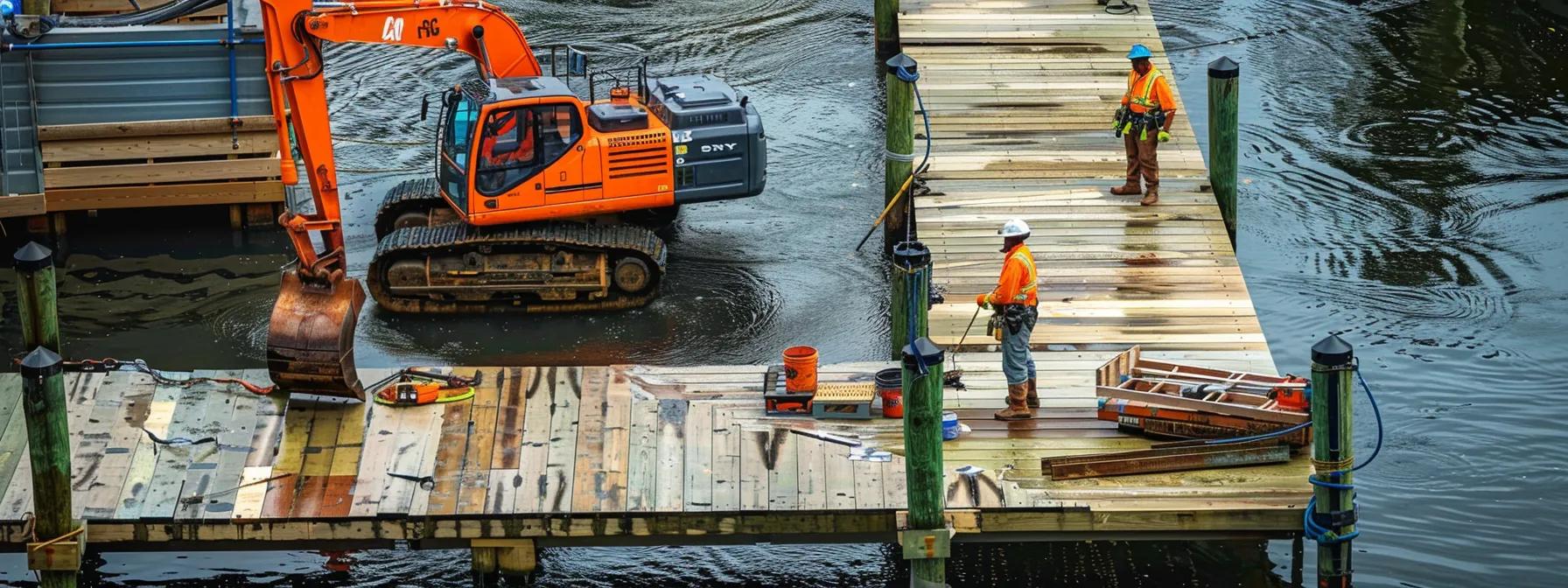

The Actual Dock Building Phase How Long Does Construction Take

After pre-construction activities are complete, the physical building phase begins. Understanding the time estimates for each construction stage is essential for setting a realistic overall timeline.

Foundation and Piling Installation Time Estimates

Installing the foundation and piling creates the dock’s structural base and is crucial for long-term stability. Piling is typically installed with heavy machinery; simple projects may complete piling in under a week while more extensive builds can require two weeks or more. If deep pilings are needed due to soft soil, additional reinforcement techniques may be necessary. This phase depends on both equipment availability and skilled labor, so any delays in either can extend the timeline.

Framing and Decking Assembly Duration

After the foundation is in place, framing and decking assembly begins. This stage involves constructing the structural framework, installing decking, and ensuring a secure, level surface. For a standard residential dock, this phase typically takes one to two weeks. However, custom joints or specialized materials like composite decking may add complexity and time to the assembly process. Efficient delivery and close coordination among teams are crucial to staying on schedule.

Installation of Accessories and Finishing Touches

Once the primary structure is complete, contractors install accessories and finishing touches such as railings, boat lifts, and lighting systems. These elements improve the dock’s functionality and aesthetic appeal while meeting safety standards and regulatory requirements. Depending on the extent of customization, this phase can take several days to a week. High-end features or custom-built accessories may require more time if manufacturer specifications must be followed closely.

Factors Causing on-Site Delays During the Build

Despite careful planning, unforeseen factors may cause delays during construction. Inclement weather, such as heavy rain or high winds, can force work stoppages for safety. Unexpected site conditions—like hidden obstructions or unstable soil—might need immediate remediation. Additionally, labor shortages, equipment failures, or material delivery delays can disrupt the schedule. Recognizing these factors allows you to plan contingencies and work closely with your contractor to maintain a flexible timeline.

How Long Does the Typical Dock Construction Project Take From Start to Finish With Variable Factors

The total duration of a dock construction project varies with factors such as weather, contractor efficiency, and unexpected issues. Here, we examine these variable elements.

Weather Conditions and Their Potential to Shift Timelines

Weather is highly unpredictable, especially on waterfronts. Rain, high winds, or storms can abruptly halt construction and extend the timeline. In many regions, selecting the dry season for construction minimizes the risk of delays. Contractors often add extra days into their schedules to account for weather-related disruptions. Monitoring local forecasts and planning during more stable periods can significantly reduce these risks.

Contractor Experience and Efficiency in Project Completion

The expertise of your chosen contractor greatly influences the project timeline. Experienced dock builders know how to anticipate issues and maintain a smooth workflow. They utilize proven methods and modern equipment to expedite various stages of construction. In contrast, less experienced contractors may face delays due to inefficiencies. Evaluating past project performance and client testimonials helps ensure that your contractor will keep the project on track.

Managing Unexpected Issues and Changes During Construction

Even well-planned projects may encounter unexpected issues, such as design changes or unforeseen site conditions. When these arise, proactive communication and effective change management are essential. Additional consultations, design revisions, or material orders may be required, each extending the timeline. Regular progress meetings and built-in flexibility in your budget and schedule help quickly resolve these challenges without compromising quality or safety.

Seasonal Influences on Dock Building Speed

Seasonal variations, including temperature and sunlight availability, also affect construction speed. In cooler climates, slower concrete curing and reduced daylight can extend foundation work. In hotter weather, faster drying times may require careful quality control during installation. Aligning your project schedule with favorable seasonal conditions helps maximize productive work hours and ensures a smoother build process.

Post-Construction and Finalizing Your Dock Project Timeline

After the main construction phase, several post-construction activities are necessary to ensure that your dock is safe, functional, and ready for use.

Scheduling and Completing Final Inspections

Final inspections serve as the official quality check before your dock is approved for use. They typically involve safety assessments and compliance verifications with local building codes and marine regulations. This process may take one to two weeks, especially if minor defects need addressing. Contractors usually schedule these inspections in advance and coordinate with local authorities to resolve any issues quickly.

Addressing Any Punch List Items or Adjustments

After construction, a “punch list” of minor adjustments is created. Tasks on this list might include sanding rough edges, touch-up painting, or fine-tuning installed accessories. Addressing these items typically takes a few days to one week. Completing the punch list ensures every detail is attended to, elevating the dock’s overall quality.

Understanding Clean-Up and Site Demobilization Time

Once punch list items are completed, the clean-up and demobilization process begins. This stage involves removing excess materials, disposing of construction waste properly, and restoring the site. Depending on the site size and debris, clean-up can take several days. Efficient demobilization not only signals the end of active construction but also prepares the area for regular maintenance.

When Can You Realistically Start Using Your New Dock

After final inspections, adjustments, and clean-up, your new dock is ready for use. Typically, immediate use is possible once final approvals are received and the area is secured. However, it is wise to wait a few extra days to allow protective coatings or sealants to fully cure and for the structure to settle.

Final Thoughts

Your dock construction process is a journey from the initial consultation through permitting, pre-construction planning, on-site assembly, and post-construction finalization. Every phase—from material procurement to final inspections—affects the overall timeline. By understanding these intricacies and planning accordingly, you ensure that your dock is built safely, on schedule, and to high standards. With careful management, you can enjoy your custom dock for years to come.

Frequently Asked Questions

Q: How can I reduce delays during the permitting process for dock construction? A: Work with an experienced permitting consultant and maintain clear communication with local regulatory authorities. This ensures that all necessary permits and environmental reviews are completed promptly, addressing issues early in the process.

Q: What materials are most effective for a speedy dock construction project? A: Marine-grade wood or composite decking typically allow for faster assembly due to easier installation. In contrast, materials like concrete or metal may require additional curing or specialized installation methods, potentially extending the timeline.

Q: How do weather conditions specifically affect the building of a dock? A: Heavy rain, high winds, or extreme temperatures can force work stoppages for safety reasons. Scheduling projects during stable weather periods or allowing extra time for weather delays helps mitigate these issues.

Q: When should I schedule inspections to avoid long delays in my dock project? A: Scheduling final inspections immediately after construction and coordinating with local authorities can help minimize delays. Typically, plan for a one- to two-week inspection phase to ensure all work meets regulatory standards.

Q: What role does contractor experience play in the overall timeline of dock construction? A: Experienced contractors use efficient work practices, timely problem resolution, and robust scheduling, significantly reducing construction time. Their expertise helps keep the project on track.

Q: Are custom features like boat lifts likely to add significant time to my dock project? A: Yes, custom features often require extra design and installation time. Discussing these aspects during initial consultations is essential since adding items such as boat lifts or custom railings can extend the project by several days or weeks.

Q: How soon after project completion can I safely use my new dock? A: Once final inspections, adjustments, and clean-up are complete, your dock is typically ready for use. It is advisable to wait a few extra days after final approval to ensure that any protective coatings have fully cured and the structure has settled.